Cutting and Marking Cutting and Marking

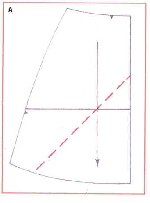

Once you fall in love with the properties of bias, you can create interesting design effect, including a softer drape or a closer-to-the-body fit, by converting all or part of a garment from straight grain to bias. To do this, draw a line perpendicular to the pattern's lengthwise grainline. Fold the pattern so these two right angle lines meet (A). this intersecting crease is the new bias grainline.

The first step in cutting out any bias garment is making sure the fabric is perfectly on-grain. To establish the crosswise grain, snip one selvage edge, then pull on a crosswise thread until the fabric puckers. Cut along the puckered line, across the width of the fabric. Align one corner of the fabric with the corner of your cutting surface or with a right angle square. If the edges do not align, do one of the following:

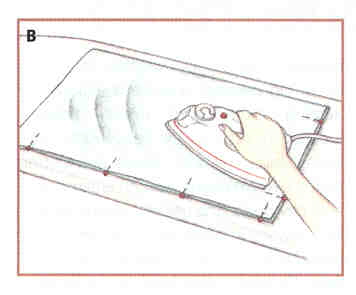

- Establish the crosswise grain at the other end of the fabric. Fold fabric lengthwise in half, right side together. Match edges and pin at 5" (12.5cm) intervals. Steam-press to straighten fabric (B)

- Pull the fabric in the opposite direction from the way the ends slant until a right angle is formed (C)

Once the fabric is grain perfect, you're ready to cut. To avoid distorting fabric, work on a large, flat cutting surface. For better control, cut your garment single layer. Use tissue paper or nonwoven pattern duplicating material to reproduce the necessary pattern pieces.

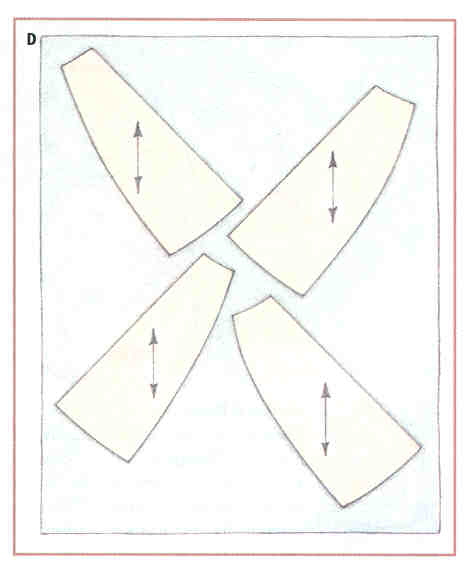

Technically, a woven fabric has two bias grains - one that angles to the right, the other to the left. If all fabrics had the same number of threads per inch in the lengthwise and crosswise directions, these two biases would behave in exactly the same way on the same piece of fabric. The fact that this is rare explains why, even careful handling, one side of a bias garment may stretch more than the other. For corresponding right and left garment sections, how you place the pattern on the fabric can minimize this problem. If your fabric has a right side and a wrong side, place the right and left pattern pieces at right angles to each other. (D) Technically, a woven fabric has two bias grains - one that angles to the right, the other to the left. If all fabrics had the same number of threads per inch in the lengthwise and crosswise directions, these two biases would behave in exactly the same way on the same piece of fabric. The fact that this is rare explains why, even careful handling, one side of a bias garment may stretch more than the other. For corresponding right and left garment sections, how you place the pattern on the fabric can minimize this problem. If your fabric has a right side and a wrong side, place the right and left pattern pieces at right angles to each other. (D)

When it comes to bias, a few "extras" at the layout stage will make the sewing part easier.

Increase all seam allowances to 1½" (3.8cm) to allow for any fitting adjustments caused by the stretching of the bias. When fabric is cut along the bias, the intersecting threads fan out, elongating the cut edge. Moving the stitching line farther away from this "expansion" will help eliminate rippled seams later on. This extra seam allowance will come in handy if you decide you want a slightly looser fit.

Before laying out the fabric, cover the cutting surface with a layer of tissue paper. (Smooth-surfaced examining table paper, available in rolls from medical supply stores, is an easy-to-use, economical version of tissue paper.) pin and cut through both layers. Leave the paper stabilizer intact until appropriate seams have been staystitched.

Mark all stitching lines before removing the pattern from the fabric. Thread tracing, chalk or tracing paper (also called dressmaker's carbon) and a tracing wheel are good choices.

Stitching

The key to successful bias sewing is to work with the stretch, not against it. Begin by staystitching any seam that will not hang vertically on the finish garment. This includes necklines, armholes, waistlines and asymmetrical seams. Do this before removing the stabilizer.

Garments cut on the bias fit differently than garments cut on straight grain. It is wise to baste the garment together, allow it to hang for 24 hours, and try it on before doing any permanent stitching. Hand-basting, using the follow technique, is essential. It guarantees accuracy for a good fit, and it provides the "give" to stitch ripple-free seams.

Vogue Patterns July/August 1997

|